Lots of ink has been spilled on how De Beers and the Federal Trade Commission (FTC) — via the release of the Lightbox lab-grown collection and an updated definition for diamonds, respectively — have boosted synthetics’ acceptance in the jewelry world. But in other fields, lab-created diamonds have been not just acceptable, but sought-after, for a long time. Their gemological properties make them valuable in sectors as diverse as military technology, aerospace engineering and health care.

Not only are lab-grown diamonds exceptionally hard, they can also run hotter than most other industrial materials without degrading in performance, and can tolerate higher voltages before breaking down. They use energy more efficiently than previous resources, have unmatched clarity in sound reproduction, and are chemically and biologically inert, meaning they can withstand extreme chemical, physical and radioactive environments that would destroy other materials.

With such a wide range of attributes, lab-grown diamonds qualify as a “supermaterial,” according to Jason Payne, founder and CEO of San Francisco-based retailer Ada Diamonds, which specializes in synthetic-diamond jewelry.

Of course, different methods of production create diamonds suitable for different purposes. High Pressure-High Temperature (HPHT) involves imitating the natural conditions in which diamonds form. This type of diamond — first commercially manufactured in the 1950s — is largely used in the construction industry for drill tips and abrasives. In contrast, chemical vapor deposition (CVD) — which entails growing a diamond layer by layer in a chamber filled with ionized gas — has been prevalent since the late 1980s and produces diamonds that work well in the high-tech and medical industries.

Natural may not cut it

This begs the question: Wouldn’t natural diamonds have the same attributes? The answer is no, according to Pascal Gallo, CEO of Switzerland-based synthetic-diamond producer LakeDiamond.

Mined stones lack many of the characteristics that make lab-grown ones useful for industrial purposes, he explains. “Naturally-mined diamonds have limited potential because their quality is inherently uneven. Ultra-pure lab-grown diamonds, however, present no such restraints. They can be engineered consistently, under controlled conditions and at scale.”

The market potential for lab-created diamonds is significant, he adds, thanks to advancements in diamond purity, miniaturization, doping (to reveal the diamonds’ semiconductor properties), and carbon isotopes. These enable the stones to meet the requirements of increasingly sophisticated applications. In fact, the potential for long-term growth and profitability is higher for industrial synthetics than it is for gem-quality lab-growns, according to Bain & Company’s 2018 global diamond report.

Approximately 15 billion carats of lab-created diamonds per year go toward industrial use, the consultancy group estimates, and that number is expected to grow exponentially over the next 10 to 15 years as companies identify new applications for these stones.

Innovations under way

De Beers’ Element Six division is perhaps the best-known producer of industrial synthetic diamonds, with departments devoted to technological and abrasive uses. But it’s not the only one with projects under way.

LakeDiamond, for instance, is in the process of launching a sustainable solution for energy distribution. Power beaming — which uses a lab-grown-diamond-bearing laser to transmit energy — will make it possible to convey electricity wirelessly, at the speed of light, over long distances so it can reach underdeveloped areas, the company explains. The technology has the potential to create job opportunities and cultural development.

Meanwhile, when it comes to many optical and electronic applications, lab-grown diamonds surpass other substances in the “wide-bandgap” class of materials, notes Mark Newton, professor of experimental physics at the University of Warwick in Coventry, England. Together with some of the university’s PhD students, Newton runs a research group dedicated to identifying the properties and uses of lab-grown diamonds.

Another party interested in industrial synthetic diamonds is the government of Flanders, Belgium, which plans to invest EUR 2 million (approximately $2.3 million) in creating a production facility for such stones, according to Philippe Muyters, the region’s minister for economy and innovation. The project is a joint venture with Indian synthetics producer Heyaru Engineering, which will contribute $27.5 million.

The idea is to create “a knowledge cluster” that would let companies share their information on the potential implementations of lab-grown diamonds, says Muyters.

Getting ambitious

The versatility of lab-grown industrial diamonds means producers can be “ambitious” when it comes to future plans, says Gallo. While LakeDiamond currently grows 15,000 synthetic-diamond plates per year, it expects to multiply that number to 300,000 by 2020.

“Today, we transform diamonds into micromechanical parts for the Swiss watchmaking industry. We are also developing diamond-based lasers and have embarked on research into diamond transistors. Our long-term vision extends to R&D on diamond-based semiconductors and biotech applications,” he states. “With their extraordinary properties, these diamonds significantly improve efficiency, productivity and value, and could revolutionize energy management, telecommunications, medicine

and computer science.”

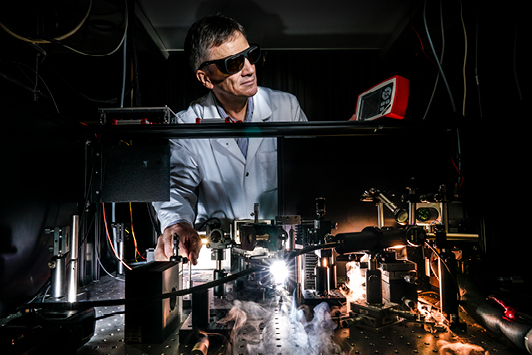

Image: Growing industrial diamonds at LakeDiamond.Article from the Rapaport Magazine - February 2019. To subscribe click here.