|

|

|

Technology

Inclusion Mapping

By Shuan Sim

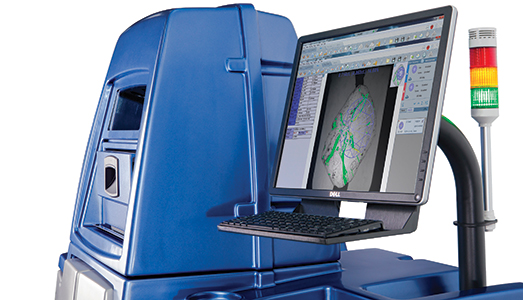

| Galaxy 1000 showing scanned diamond. Photo courtesy Sarine.

|

Historically, diamond cutters inspected stones for flaws with their eyes and a loupe. Eventually, computers aided them in calculating the location of the flaws, but a window still had to be cut to reveal a diamond’s interior. In 2009, Sarine Technologies, based in Israel, took a large part of the guesswork out of the equation and introduced the first product in its line of inclusion-mapping machines — the Galaxy 1000. It was capable of automatically scanning and mapping the inclusions of a rough diamond without the need for a window. As technology improved, Sarine introduced machines capable of faster output and higher cost savings, resulting in its latest, the Galaxy Meteor, launched in December 2015. Sarine’s Galaxy mapping systems utilize a camera that takes a video of the exterior of the stone and a proprietary scanner that maps the interior of the stone. “It’s similar to magnetic resonance imaging (MRI) that you see in hospitals,” explains Tommer Raif, sales director at Sarine. “It’s a breakthrough in material engineering that allows us to make the diamond clear and see-through.” Subsequent advancements in lenses, lasers and computer algorithms allowed Sarine’s mapping systems to scan more accurately, as well as to scan larger stones. “The game changer was really when we introduced the Galaxy Ultra in 2014,” Raif says. “Using a new microscopic system, we are able to achieve very high-resolution detection of inclusions up to one micron.” The Galaxy Ultra, along with the Galaxy Meteor, also directly feed scanned data to Sarine’s diamond planning system, Advisor, which visualizes the number of diamonds that can be cut from a rough stone.GALAXY 1000- Diamonds up to 13 mm wide, around 20 carats.

- Processes on average five stones per hour from VS to I3.

- Leaves laser marks to align the exterior model to Galaxy's video file.

GALAXY 2000- Only available at Sarine’s service centers.

- Similar specifications to 1000 but does not leave laser marks.

GALAXY XL- Only available at Sarine’s service centers.

- Diamonds up to 32 mm wide, around 180 carats.

- Processing takes one to two hours per stone, depending on size, in clarities VS2 to I3.

SOLARIS 100- Diamonds up to 7 mm wide, around 2.5 carats.

- Processes on average six stones per hour from VS to I3.

GALAXY ULTRA- Diamonds up to 13 mm wide, around 20 carats.

- Ultra mode scans inclusions up to one micron wide.

- Processes around 20 stones per day in Ultra mode, depending on stone size, and four stones per hour in Galaxy mode.

- Capable of scanning from VVS1 to I3 clarity.

GALAXY METEOR- Diamonds up to 6 mm wide, around .89 carats. Uses 3-D laser scanning to provide an accurate 3-D model of the stone.

- Processes around nine stones per hour from VS to I3.

Article from the Rapaport Magazine - October 2016. To subscribe click here.

|

|

|

|